How Acoustic Imaging is Increasing Efficiency in the Petrochemical Sector

How Acoustic Imaging is Advancing Efficiency in the Petrochemical Industry

Introduction: The petrochemical industry stands as a backbone of modern civilization, supplying a wide range of essential raw material products, from everyday plastics to high-performance synthetic fibers. This sector is not only crucial for manufacturing but also plays a significant role in driving economic growth globally. With six of the world’s ten largest industries connected to petrochemicals, the oil and petroleum sector plays a vital role in the global economy.

However, the petrochemical industry faces a growing set of challenges as it faces a growing set of technological and environmental challenges. As the need for efficiency, safety, and sustainability grows, the industry is always pressured to find new solutions and make changes. One of the most pressing issues is the management of wastewater generated during production processes. Petrochemical wastewater is prominent for its high concentrations of harmful organic materials, including toluene, xylene, phenols, and benzene, all of which contribute to increased chemical oxygen demand (COD) and biological oxygen demand (BOD) levels. In some cases, the COD of this wastewater can reach levels as high as 11,500 mg/L, posing severe risks to both environmental and human health.

These organic components are particularly challenging because of their slow degradation rates, meaning they can persist in the environment for longer time, potentially causing long-term ecological damage. Additionally, petrochemical wastewater often contains volatile organic compounds (VOCs), solubilized minerals, and polycyclic aromatic hydrocarbons (PAHs), which further complicate treatment efforts and amplify the environmental impact.

As the industry grows, it’s crucial to find effective ways to address these challenges. Innovating in areas such as wastewater treatment, pollution control, and sustainable practices is not just beneficial but essential for the long-term probability of the petrochemical sector. Addressing these issues will not only enhance operational efficiency but also contribute to a safer, more sustainable future for both the industry and the planet Earth.

The Importance of Acoustic Imaging in Petrochemical Operations

What is Acoustic Imaging?

Acoustic imaging is an innovative and modern development in the technology used within the petrochemical industry. At its core, acoustic imaging is the process of visualizing sound waves, a concept that allows engineers to gain valuable insights into the inner workings of industrial machinery and systems. By capturing the way sound travels and interacts with different materials, acoustic imaging provides a detailed map of acoustic energy distribution across various surfaces and components.

This innovative technology is transformative for the petrochemical sector, where operational efficiency and safety are very crucial. Traditional methods of monitoring equipment often involve invasive techniques or require partial shutdowns to inspect machinery for potential issues. Acoustic imaging, however, offers a non-invasive solution that can detect irregularities such as leaks, wear and tear, or structural weaknesses without interrupting operations. By translating sound into visual data, engineers can quickly and accurately identify areas of concern, leading to faster diagnostics and targeted maintenance.

The impact of acoustic imaging on petrochemical operations is beneficial. It not only enhances the precision with which potential problems are identified but also significantly reduces the time and resources needed to address these issues. As a result, companies can minimize downtime, reduce operational costs, and, most importantly, improve safety standards by preventing accidents before they happen. In an industry where even minor faults can lead to significant environmental and financial consequences, acoustic imaging stands out as a crucial tool for ensuring smooth, safe, and efficient operations.

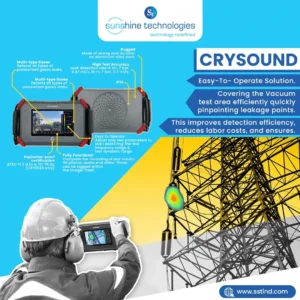

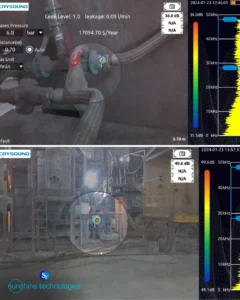

The Role of CRYSOUND Acoustic Imaging Camera

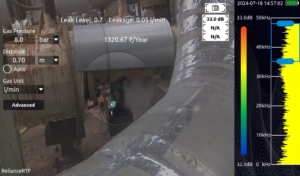

The CRYSOUND Acoustic Imaging Camera is a tool that plays a crucial role in advancing the petrochemical industry. This modern device allows engineers to detect and visualize sound waves, marking potential issues in machinery with unmatched precision. By identifying sound anomalies such as leaks, unusual vibrations, or mechanical damage, the CRYSOUND camera provides critical insights that help prevent small problems from growing into costly failures. What makes this technology particularly valuable is its ability to perform these diagnostics in real time, without the need for operational shutdowns, thus minimizing downtime and reducing the risk of unexpected equipment breakdowns.

Beyond detection, the CRYSOUND Acoustic Imaging Camera enhances the efficiency of maintenance activities by delivering detailed visual data. This enables maintenance teams to target specific areas of concern, optimizing their efforts and resources. Additionally, the early detection capabilities of the CRYSOUND camera contribute significantly to safety in the petrochemical industry, helping to prevent environmental hazards and protect workers from potential accidents. By combining precise diagnostics with non-invasive monitoring, the CRYSOUND Acoustic Imaging Camera is changing petrochemical companies’ approach towards machinery maintenance and safety, making it a required tool in modern operations.

Benefits of Acoustic Imaging Technology

- Precise Detection: One of the most significant advantages of acoustic imaging technology is its ability to mark problem areas with exceptional accuracy. Unlike traditional inspection methods, which may miss critical issues, acoustic imaging captures sound waves emitted by machinery and transforms them into visual data. This allows engineers to precisely identify potential faults, such as leaks, unusual vibrations, or equipment wear, long before they develop into serious problems. By offering such precise detection, acoustic imaging minimizes the risk of undetected issues that could lead to costly operational downtime, ensuring that maintenance can be performed proactively rather than reactively.

- Cost Efficiency: Acoustic imaging technology also offers considerable cost savings for companies in the petrochemical industry and beyond. Early detection of issues through this technology means that minor faults can be addressed before they grow into major repairs or system failures. This proactive approach reduces the need for extensive repairs and prevents unexpected shutdowns, which can be extremely expensive in terms of both direct repair costs and lost productivity.

- Enhanced Safety: Safety is a paramount concern in any industrial setting, and acoustic imaging technology plays a crucial role in enhancing workplace safety. The ability to detect leaks, equipment malfunctions, or other abnormalities in real-time means that potential hazards can be identified and addressed before they pose a serious threat. For instance, detecting a small leak early on can prevent a larger, more dangerous spill that could harm workers or the environment.

Sustainability Through Early Detection

Environmental Responsibility in Petrochemicals: The petrochemical sector, known for its huge impact on the environment, is increasingly turning to advanced technologies to enhance its environmental responsibility. One such innovation is the CRYSOUND Acoustic Imaging Camera, which plays a pivotal role in this effort. By enabling early detection of leaks and other potential issues, this technology helps prevent the release of harmful substances into the environment.

Reducing Environmental Footprint

- Leak Prevention: One of the primary ways to reduce the environmental footprint of petrochemical operations is through effective leak prevention. The early detection of leaks is crucial in this regard, as it helps to prevent the release of harmful chemicals into the environment. Technologies like the CRYSOUND Acoustic Imaging Camera play a significant role by providing precise and timely identification of potential leak points. By addressing these issues before they result in significant emissions or spills, companies can significantly reduce their environmental impact. Early detection not only protects natural resources but also helps in adhering to environmental regulations and standards.

- Operational Efficiency: In addition to leak prevention, maintaining optimal equipment performance is essential for minimizing environmental impact and sudden failure of machinery. When equipment operates efficiently, it consumes less energy and generates less waste, which directly contributes to a reduced carbon footprint. The CRYSOUND Acoustic Imaging Camera aids in this by ensuring that machinery is functioning at its best by identifying and addressing issues before they affect performance. This proactive maintenance approach helps in avoiding breakdowns and inefficiencies that could lead to increased energy consumption or the production of excess waste.

Collaborative Innovation

Industry Partnerships Driving Progress: The integration of advanced technologies such as acoustic imaging into the petrochemical industry highlights the significant benefits of collaborative innovation. This partnership between petrochemical companies and technology developers, illustrated by the collaboration with CRYSOUND, underscores how working together can drive substantial progress in various operational aspects. By engaging with technology providers, petrochemical firms gain access to the best solutions that can be easily incorporated into their existing systems.

This collaborative approach allows for the continuous enhancement of key operational areas including efficiency, safety, and sustainability. For instance, CRYSOUND’s acoustic imaging technology offers remarkable precision in detecting equipment issues and potential leaks, which in turn helps petrochemical companies improve their maintenance strategies and operational practices. The synergy between industry experts and technology developers facilitates the adoption of innovative tools that not only advance operational efficiency but also support safety protocols by enabling early detection of potential hazards.

The Future of Petrochemical Operations

Innovation as a Catalyst for Change: As the petrochemical industry continues to progress, innovation plays an increasingly crucial role in shaping its future. The adoption of advanced technologies like acoustic imaging is set to revolutionize the way the industry operates. Acoustic imaging, in particular, offers unparalleled precision in detecting and diagnosing equipment issues, helping to prevent costly failures and enhance overall operational efficiency. By investing in such technologies, the petrochemical sector can achieve more accurate maintenance, reduce downtime, and minimize its environmental impact.

Moreover, Establishing strong partnerships between technology developers and petrochemical companies is accelerating technological advancement. These collaborations enable the continuous refinement of tools and the creation of customized solutions that address specific industry needs. As the industry adopts these partnerships and innovative solutions, it not only improves its current operations but also lays the groundwork for future growth and sustainability.

Conclusion: The integration of acoustic imaging technology, particularly through innovative tools like the CRYSOUND Acoustic Imaging Camera, is marking a significant positive change in the petrochemical industry. This advanced technology is transforming how the industry operates by offering unparalleled precision in detecting and diagnosing equipment issues. The ability to accurately pinpoint potential problems before they escalate not only enhances operational efficiency but also significantly improves safety standards across petrochemical plants.

Moreover, the CRYSOUND Acoustic Imaging Camera is playing a pivotal role in advancing the industry’s sustainability goals. By reducing the possibility of equipment failures and minimizing unplanned downtime, the technology contributes to more efficient use of resources, which in turn lowers the environmental impact of petrochemical operations. As the industry faces the dual pressures of maintaining high productivity and adhering to stringent environmental regulations, acoustic imaging technology is empowering it to meet these challenges effectively and efficiently.

Connect with us: Enhance your petrochemical operations with cutting-edge CRYSOUND Acoustic Imaging technology from Sunshine Technologies. Visit our website at Sunshine Technologies and connect with us on Instagram, LinkedIn, Facebook, and YouTube for more insights and updates on industrial acoustic imaging solutions.

FAQS

- What is acoustic imaging, and how is it used in the petrochemical industry?

- Acoustic imaging is a technology that visualizes sound waves to create detailed maps of acoustic energy distribution across industrial machinery and systems. In the petrochemical industry, it is used to detect irregularities such as leaks, wear, and structural weaknesses, all without interrupting operations.

- How does the CRYSOUND Acoustic Imaging Camera benefit petrochemical operations?

- The CRYSOUND Acoustic Imaging Camera enhances petrochemical operations by providing precise, real-time detection of sound anomalies like leaks and mechanical damage. This allows engineers to identify potential issues before they escalate, reducing downtime, preventing costly failures, and improving safety standards.

- What are the environmental benefits of using acoustic imaging technology in the petrochemical sector?

- Acoustic imaging technology, such as that provided by the CRYSOUND Acoustic Imaging Camera, plays a crucial role in environmental protection by enabling early detection of leaks and other issues that could lead to harmful emissions. By preventing the release of toxic substances into the environment and ensuring efficient machinery performance, this technology helps reduce the industry’s environmental footprint and supports compliance with environmental regulations.

- Why is early detection important in petrochemical operations?

- Early detection is important in petrochemical operations because it allows for proactive maintenance, which can prevent minor issues from escalating into major failures. By identifying problems like leaks or equipment malfunctions early, companies can avoid costly repairs, minimize downtime, and prevent environmental hazards, ultimately leading to safer and more efficient operations.

- How does acoustic imaging contribute to cost efficiency in the petrochemical industry?

- Acoustic imaging contributes to cost efficiency by allowing early identification of potential issues, which can be addressed before they cause severe damage. This proactive approach reduces the need for extensive repairs and prevents unexpected shutdowns.

- How does acoustic imaging technology improve safety standards in petrochemical plants?

- Acoustic imaging technology improves safety standards by providing real-time, precise detection of equipment abnormalities such as leaks and mechanical issues. By identifying potential hazards early, the technology helps prevent accidents, protects workers, and reduces the chances of environmental incidents.

- What challenges does the petrochemical industry face, and how does acoustic imaging address them?

- The petrochemical industry faces challenges related to efficiency, safety, and environmental sustainability. Acoustic imaging addresses these challenges by offering a non-invasive, precise method for detecting equipment issues before they cause heavy damage.